ASSESS YOUR PERFORMANCE AND SEE SUSTAINABLE SOLUTIONS

maintain Supply Chain Performance

Maximize Logistics Efficiency

Maximize Logistics Efficiency

Maximize Logistics Efficiency

Continuously improve Supply Chain work, processes, and tools to create and keep a competitive advantage

A Continuous Improvement Culture

+ Innovate with Quality Management System

+ Apply Lean and PDCA methodologies

+ Use KPIs and RCA for effective changes

+ Empower and reward employee improvement

Why it Matters: Growth can improve efficiency with an innovative mindset for resource efficiency and waste elimination within a regenerative process and service designs.

Mitigate Supply Risks

Maximize Logistics Efficiency

Maximize Logistics Efficiency

Proactively identify and evaluate risks and apply appropriate levels of protection with a Risk Management Program

Prepare and Respond to Disruptions

+ Apply a Business Continuity Planning System

+ Exercise Emergency Response Plans

+ Mitigate risk with sourcing program

+ Build supplier resiliency

Why it Matters: Threats to supply chains and brands are growing with climate change, cybersecurity exposures and threats, and geopolitical interdependence and instability.

Extending Lifecycle Value

Maximize Logistics Efficiency

Extending Lifecycle Value

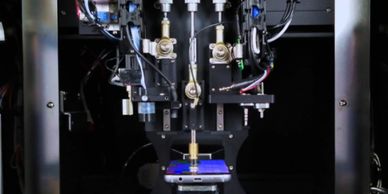

Circularity takes design & maintenance to maximize product life, reselling assets to meet new demand, and recycling to close the resource loop and retain value

A Total Cost of Ownership Approach

+ Apply Lifecycle Cost Analysis in Design

+ Design for Repair, Reuse, and Recycling

+ Advance circularity with resale and recycled material content

+ Reduce packaging and transportation

Why it Matters: The linear make-to-waste process is unsustainable, with elevated costs and GHG emissions. Circularity creates a resource loop, eliminates waste, and generates sustainable value.

Copyright © 2021 SEE Sustainable Solutions, LLC - All Rights Reserved.

Designed by S.R.S

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.